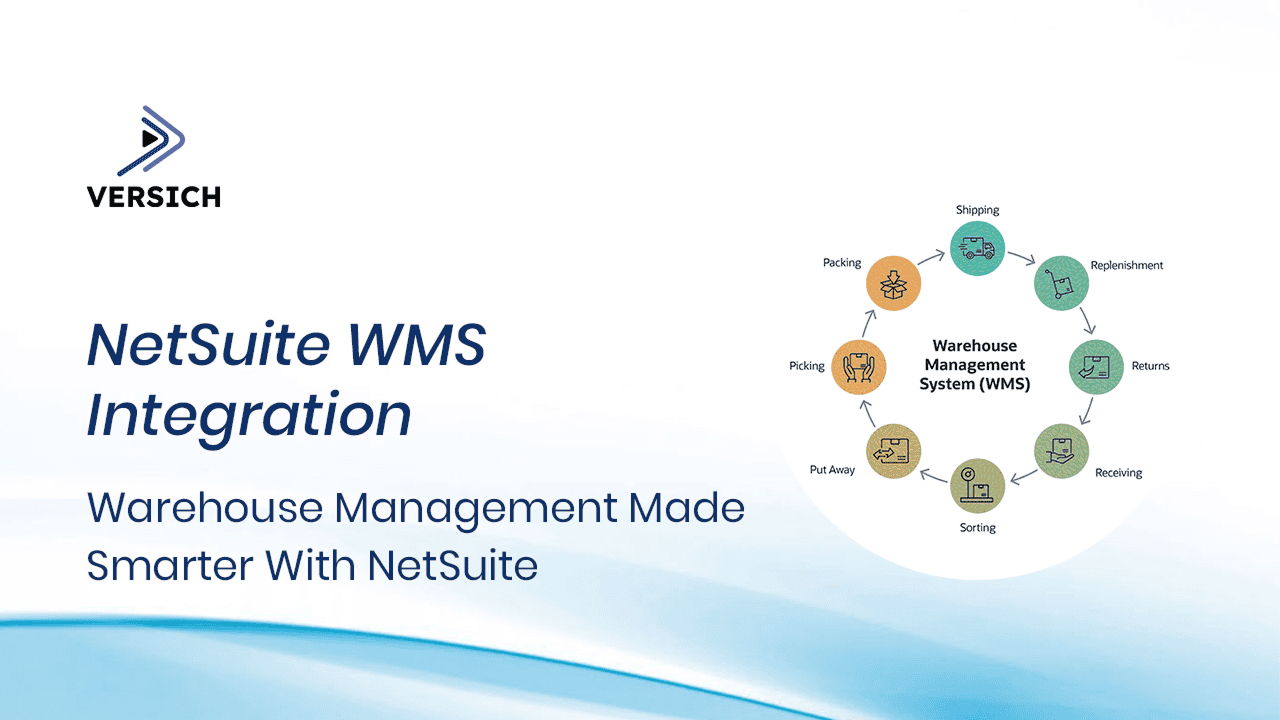

In today’s high-volume, multi-channel fulfillment environment, NetSuite WMS Integration transforms how warehouses operate by uniting execution, inventory, and fulfillment inside one ERP ecosystem.

Unlike external WMS platforms that rely on cross-system syncing, NetSuite WMS runs on the same real-time database as inventory, order management, and manufacturing. This eliminates latency and data reconciliation issues while maintaining a single version of operational truth.

Its success, however, depends on clean item and bin data, well-structured RF/mobile workflows, and seamless handoffs between warehouse, fulfillment, and shipping layers.

NetSuite WMS Integration connects warehouse execution directly to NetSuite’s inventory and fulfillment modules, eliminating external syncs and enabling real-time scanning, picking, packing, and shipping within one system.

What is NetSuite WMS?

NetSuite WMS is a native warehouse management system (WMS) module that sits entirely inside the NetSuite ERP environment, sharing the same item, bin, order, and fulfillment data used across the business.

It supports RF barcode scanning, intelligent putaway, mobile picking, cycle counting, and returns processing using live inventory data. Because it’s not a bolt-on product, there’s no separate database or synchronization process; everything updates in real time.

NetSuite WMS Integration enables warehouse operations, receiving, picking, packing, and counting to run natively inside NetSuite, sharing the same records as order management and manufacturing, eliminating cross-system syncs.

Scope and Capabilities

Function | Description |

Receiving & Putaway | Mobile RF capture of incoming goods, lots, serials, and directed putaway to optimal bins. |

Picking & Tasking | Wave creation, guided RF picks, and workload balancing by priority or promise date. |

Packing & Shipping | Integration with NetSuite’s built-in shipping engine for labels and tracking. |

Cycle Counting & Smart Count | Continuous, real-time counts without freezing the entire location. |

Returns (RMA Receiving) | Mobile receipt of returns with immediate stock re-entry visibility for CX and finance. |

NetSuite WMS is a warehouse management software module embedded within NetSuite ERP, enabling barcode scanning, directed picking, and mobile tasking that updates inventory and orders in real time no third-party sync required.

Business Outcome

Implementing WMS for NetSuite aligns warehouse execution with upstream orders and downstream fulfillment, drastically reducing manual data entry and operational silos.

Because every scan updates NetSuite directly, organizations gain real-time visibility into on-hand quantities, pick progress, and fulfillment status across multiple sites.

Key Business Results

Area | Benefit |

Operations | Shorter dock-to-stock time and higher pick accuracy via RF guidance. |

Inventory Accuracy | Eliminates double handling and mismatched counts. |

Labor Efficiency | Reduces manual entry, paper pick lists, and administrative overhead. |

Customer Experience | Improves order accuracy and on-time shipping performance. |

Scalability | Enables multi-site expansion without needing additional middleware or integrations. |

Businesses adopting NetSuite WMS Integration reduce fulfillment errors and manual reconciliation by operating warehouse, inventory, and shipping on one unified ERP dataset.

Integration Architecture

1. Native Suite Integration

NetSuite WMS operates directly on NetSuite’s unified data model. This means inventory, order fulfillment, and manufacturing share a single, real-time record set. Thus, the “integration” isn’t between two different systems; it’s a configuration of process flows within the same system.

Key Components:

Inventory and Items: Shared tables across WMS, order management, and accounting.

BOM and Manufacturing: Pull materials directly from WMS-managed bins.

Fulfillment and Billing: Trigger automatically once pick/pack tasks are complete.

Note:

The only “integration” boundaries appear at shipping and hardware layers, where carrier APIs and mobile devices interact with WMS.

2. External Touchpoints

Even though NetSuite WMS is self-contained, it integrates outward to peripherals and carriers to complete the logistics loop.

Layer | Integration Type | Description |

Shipping Systems | NetSuite Carrier Integrations (UPS, FedEx, ShipStation, etc.) | UPS/USPS/FedEx labels, tracking, and costs sync automatically at fulfillment. |

Mobile Devices | NetSuite WMS Mobile App (RF) | Android-based handheld app for scanning, picking, putaway, and counts in real time. |

Printers and Scales | Peripheral Integrations | Label and document printing through supported devices at pack stations. |

NetSuite WMS integrates natively inside NetSuite but connects externally at shipping (carrier APIs) and mobility (RF scanners) levels no third-party middleware needed.

Core Operational Flows to Integrate

NetSuite WMS Integration manages end-to-end warehouse execution inbound, putaway, picking, packing, shipping, returns, and cycle counting — using one live data source shared across inventory and fulfillment.

Each operational process in WMS directly writes to NetSuite’s inventory and fulfillment records, so there’s no batch sync or delay. Every scan or transaction—be it a receipt, move, or shipment immediately updates on-hand inventory and availability.

1. Inbound and Putaway

Inbound processes start the warehouse lifecycle. In NetSuite WMS, mobile users can perform receiving with or without Advanced Shipping Notices (ASNs).

Flow:

Mobile receiving via handhelds captures PO number, item, lot/serial, and quantity.

System validates against open purchase orders or inbound transfers.

WMS applies putaway strategies directed (based on velocity or item attributes) or manual (operator choice).

Items are stored in bins defined by capacity and pick zone hierarchy.

The receipt instantly updates inventory availability for sales order allocation and manufacturing use.

Inbound and putaway flows in NetSuite WMS use RF scanning to record item, lot, and bin placement in real time, eliminating delays between receipt and inventory availability.

2. Wave Release and Picking

Picking is where NetSuite WMS truly differentiates itself from basic inventory modules.

Flow:

Wave release groups multiple orders based on rules—carrier cutoff, zone, or promise date.

Pick tasks are assigned to users or devices based on workload.

The RF scanner guides each operator through the most efficient route (wave, cluster, or batch picking).

Each scan validates item and bin accuracy, reducing pick errors.

Completed picks feed directly into the pack and fulfillment stages.

Smart Logic Examples:

Single-order waves for high-value orders.

Multi-order cluster picking to reduce walk time.

Zone-based tasking for large DCs.

NetSuite WMS wave picking consolidates multiple orders, guiding users through optimized RF pick paths that update fulfillment and inventory in real time.

3. Packing and Shipping

After picking, WMS hands off seamlessly to packing and shipping.

Packing:

Operators scan items into cartons.

Packing validations ensure all required lines are fulfilled.

Pack weights and dimensions can be captured for rate quoting.

Shipping:

The integrated shipping system (FedEx, UPS, or ShipStation) generates labels directly within NetSuite.

Shipping cost and tracking update automatically on the Item Fulfillment record.

Customer notifications trigger immediately with tracking URLs.

Packing and shipping in NetSuite WMS link directly with native carrier integrations, ensuring label generation, account charging, and tracking visibility are unified in fulfillment.

4. Returns and RA Receipts

Returns processing is one of the most under-optimized flows in legacy WMS systems. With NetSuite WMS, returns are handled as smoothly as outbound shipments.

Flow:

Return Authorizations (RAs) are approved in NetSuite and visible on handheld devices.

Warehouse users receive returned goods using RF scanners, capturing item, lot/serial, and condition.

The system validates disposition — restock, scrap, or quarantine.

Inventory re-entry rules ensure financial and operational alignment with customer service and finance.

NetSuite WMS return receipts ensure real-time reverse logistics visibility, updating inventory and finance as returned items re-enter stock or move to quarantine bins.

5. Cycle Counting and Smart Count

Traditional cycle counts disrupt warehouse operations by requiring location freezes. NetSuite’s Smart Count introduces continuous, real-time counting without halting activity.

Key Features:

A snapshot of item quantity is taken when a count starts.

If any transaction occurs mid-count (pick, transfer, adjustment), the counter is alerted.

Preferences determine whether to continue, restart, or reconcile automatically.

Real-time variance reconciliation improves accuracy while maintaining flow.

Governance:

Define count classes by SKU velocity (A/B/C).

Schedule high-variance or high-value SKUs for frequent counts.

Track variance reason codes for root-cause correction.

Smart Count in NetSuite WMS performs live inventory counts without freezing operations, alerting users to mid-count changes and preserving data accuracy.

Mobile / RF and Device Integration

NetSuite WMS Mobile App connects handheld scanners directly to NetSuite, enabling real-time execution of receiving, picking, packing, and counts through barcode workflows.

WMS Mobile App Overview

Available on Android devices via the NetSuite WMS Mobile App.

Provides process-specific menus (Inbound, Picking, Packing, etc.).

Connects directly to the NetSuite ERP database over Wi-Fi; no middleware required.

Designed for multi-user sessions with live transaction visibility.

RF Scanning Practices

Practice | Recommendation |

Barcode Standards | Use GS1 or Code 128 for consistency. |

Bin Labels | Include zone/aisle/rack/shelf hierarchy. |

Item Barcodes | Validate uniqueness across UoM variants. |

Batch/Cluster Picking | Test scanning flows for speed and accuracy. |

Standardize label placements and ensure bin label visibility at eye level; poor label management is one of the most common RF adoption blockers.

Bin and Location Data Model

The strength of any NetSuite Warehouse Management System depends heavily on its bin and location architecture.

Bin Management

Bins are the foundation for putaway and picking logic.

Define bins by zone → aisle → rack → shelf hierarchy.

Assign bin capacity limits to prevent overstock.

Maintain default bins for receiving, returns, and staging to avoid stranded inventory.

Multi-Location Inventory

Enable Multi-Location Inventory (MLI) to manage stock across distribution centers, retail outlets, or drop-ship hubs.

Set transfer rules for inter-location moves.

Assign each location its own fulfillment, accounting, and shipping configurations.

NetSuite WMS uses a bin-based location model to drive intelligent putaway and pick path optimization, with real-time visibility across all warehouses under Multi-Location Inventory.

Inventory Accuracy and Smart Count Governance

Smart Count in NetSuite WMS maintains real-time inventory accuracy by allowing live cycle counts that adapt to ongoing transactions, preventing disruption and improving data trust for finance and fulfillment.

1. Why Smart Count Matters

Legacy cycle-count systems pause warehouse operations to freeze locations. NetSuite’s Smart Count enables continuous counts without stopping activity using a snapshot-based approach that detects changes mid-count.

Snapshot Mechanism: Each count session captures on-hand values at the start.

Change Detection: If a pick or putaway occurs mid-count, the user receives a prompt.

Resolution Options: Admins can auto-adjust, restart, or approve variance.

Variance Reconciliation: Smart Count creates audit trails for SOX and inventory controls.

2. Governance Framework

Governance Element | Guideline |

Count Classes (ABC) | Define A/B/C by velocity or value; A = daily, B = weekly, C = monthly. |

Count Frequency Rules | Automate based on variance thresholds or last count date. |

Variance Approval | Require supervisor sign-off on > ± 5 % variance for financial accuracy. |

Root-Cause Tags | Capture reasons (e.g., mis-pick, unposted transfer, damage) to improve processes. |

NetSuite WMS Smart Count keeps operations running while counting inventory live, alerting users to changes mid-count and enforcing variance approvals for audit-ready accuracy.

Shipping Integration Touchpoints

NetSuite WMS ties directly to NetSuite’s shipping integrations, FedEx, UPS, ShipStation, so fulfillment, labeling, and tracking updates instantly without external middleware.

1. Integrated Shipping Flow

At the fulfillment stage, WMS passes packed orders to NetSuite’s native shipping engine or third-party connectors.

This ensures:

Automatic label generation and tracking capture.

UPS/FedEx account charges sync to the right location.

Shipping details link back to Item Fulfillment for finance and CX.

2. Exception Handling

Multi-package Orders: Each package returns tracking and weight data.

Freight vs Parcel: Connector rules determine rate shop vs manual LTL entry.

Failed Label Generation: Alerts trigger for address errors or API timeouts.

3. Performance Monitoring

Track label generation time and carrier API latency.

Reconcile freight variance (estimate vs invoice) each period.

Use NetSuite’s Saved Search dashboards to surface orders pending tracking.

In NetSuite WMS, shipping integrations automatically create labels and update fulfillment records with tracking data, reducing manual carrier portal entry by up to 80 %.

Data Mapping and Master Data Readiness

Successful NetSuite WMS Integration depends on clean item, bin, and UoM master data, ensuring barcode consistency and accurate RF execution.

1. Item and UoM Readiness

Validate item records for weights, dimensions, barcodes, and lot/serial flags.

Define UoM conversion ratios clearly to avoid mis-picks in RF scanning.

Set default bins and putaway preferences per item type.

For perishables or hazardous goods, use custom fields to drive storage logic.

2. Bin and Putaway Rules

Tie bin assignments to item velocity, temperature, or zone.

Ensure each receiving location has default “staging” and “returns” bins.

Run bin capacity simulations before go-live to avoid overflow.

3. Task and Wave Configuration

Map wave release rules to carrier cut-offs and order promise dates.

Define task priorities for inbound vs outbound roles.

Leverage SuiteAnalytics for real-time task completion metrics.

Proper data mapping in NetSuite WMS ensures barcode scans, bin movements, and shipping charges align accurately across inventory and fulfillment, eliminating variance and manual reconciliation.

Implementation Approach and SuiteSuccess Methodology

A phased NetSuite WMS rollout under SuiteSuccess minimizes risk, starting with receiving and putaway before expanding to waves, Smart Count, and multi-site operations.

1. Phased Enablement

Phase | Focus | Goal |

Phase 1 | Inbound & Putaway | Stabilize RF receiving and inventory visibility. |

Phase 2 | Picking & Packing | Replace paper with mobile picking; introduce pack stations. |

Phase 3 | Smart Count & Waves | Launch continuous counting and advanced wave logic. |

Phase 4 | Multi-site Expansion | Enable multi-location inventory and shipping integration. |

2. Change Management and Training

Run RF “sandbox” workshops for hands-on learning.

Monitor scan compliance rates and time per task in the first month.

Provide role-based training for receivers, pickers, and supervisors.

3. Adoption Metrics

RF Usage Rate ≥ 90 % by week 4.

Dock-to-stock time reduction ≥ 30 %.

Pick accuracy ≥ 99 % within 2 months.

SuiteSuccess implementation of NetSuite WMS uses phased enablement and RF training to achieve rapid adoption and accuracy gains without disrupting warehouse operations.

Testing Plan (Pre Go-Live)

A structured pre-go-live testing plan validates inbound, picking, packing, and Smart Count workflows under peak conditions, ensuring all integrations, devices, and data mappings perform as expected.

1. Functional Testing

Validate that all warehouse functions operate end-to-end without exception:

Function | What to Test | Expected Result |

Inbound (with/without ASN) | PO receipts, lot/serial capture | Correct bin placement and live inventory update |

Putaway Strategies | Velocity-based, temperature-based | Items directed to right bin automatically |

Wave Picking | Single vs. multi-order waves | Accurate RF guidance and task allocation |

Partial Picks | Incomplete quantities | Backorders left open, no over-ship |

Packing & Shipping | Label creation via carrier integration | Label prints, cost/track updates on Item Fulfillment |

Returns (RMA) | RA receipts and dispositions | Correct stock updates for restock/quarantine |

Smart Count | Mid-count inventory changes | Alerts triggered; variance handled properly |

2. Data Integrity Testing

Validate item scans (UPC vs internal ID) for match consistency.

Confirm bin capacity enforcement.

Ensure inventory availability updates propagate to sales order promise dates.

Check that the weight/dimension data feeds accurate carrier rate calculations.

3. Performance & Stress Testing

Run peak-hour wave releases simulating high-order volume.

Monitor RF concurrency and latency under 20+ simultaneous devices.

Test label printing throughput and printer driver resilience.

Verify Wi-Fi coverage and roaming in aisles and docks.

NetSuite WMS go-live testing should simulate real-world peak conditions, verifying RF device concurrency, Smart Count accuracy, and carrier label integration to prevent disruption post-deployment.

KPIs and Value Realization

Tracking operational, inventory, and financial KPIs validates ROI from NetSuite WMS Integration revealing efficiency gains in labor, accuracy, and fulfillment speed.

1. Operations

Lines picked per hour (LPH): +20–40% improvement typical after mobile adoption.

Pick accuracy: 99%+ with RF scanning validation.

Dock-to-stock time: Reduction from hours to minutes using directed putaway.

Order cycle time: Decrease by 25–50% with wave picking.

2. Inventory

On-hand accuracy: Maintain ≥ 98%.

Count variance rate: Target < 1.5%.

Shrinkage trend: Should reduce over 3–6 months.

Stockout/backorder rate: Drop due to real-time availability visibility.

3. Customer Experience & Cost

On-time ship rate: Exceeds 97%.

Perfect order rate: Improve to > 95%.

Handling cost per order: Decrease 10–20%.

WISMO (Where Is My Order) tickets: Reduced due to automatic tracking updates.

4. Financial Impact

Faster period close through Smart Count reconciliation.

Fewer manual adjustments and inventory write-offs.

Reduced third-party system costs (no middleware or external WMS licenses).

Businesses using NetSuite WMS Integration report faster order processing, 99% pick accuracy, and major cost reductions by eliminating manual reconciliation and third-party tools.

Common Pitfalls and How to Avoid Them

Pitfall | Impact | Preventive Measure |

Incomplete master data | RF scanning failures; wrong bins | Clean item and bin data (barcodes, weights, dims) before rollout |

Complex wave design too early | User confusion, reduced adoption | Start simple; introduce waves gradually post-stabilization |

Unmapped carrier accounts per location | Freight billed to the wrong account | Validate location-to-carrier mappings during testing |

Decoupled shipping from fulfillment | Missing tracking, manual re-entry | Keep shipping integrated within NetSuite fulfillment |

Poor Wi-Fi/RF coverage | Device disconnects mid-task | Conduct a site survey and set minimum dBm thresholds |

Lack of training | User resistance | Run role-based simulations and daily scoreboards post-go-live |

Pro Tip: The most successful WMS deployments invest early in data hygiene, and user training technology alone won’t fix bad inventory discipline.

Conclusion

The NetSuite WMS Integration isn’t just a warehouse upgrade; it’s a business transformation. By bringing warehouse execution, inventory management, and fulfillment onto a single native platform, it eliminates the traditional disconnect between ERP and WMS.

Every scan, every putaway, every shipment label, and every Smart Count adjustment flows through the same data backbone that powers finance, orders, and customer service. This unified design translates into faster decision-making, lower operating costs, and a measurable increase in fulfillment accuracy and speed.

For modern enterprises scaling across multiple facilities or channels, NetSuite WMS provides the real-time visibility and automation backbone needed to operate with confidence.

It bridges the physical and digital layers of your supply chain, connecting handheld scanners, shipping carriers, and financial reconciliation into one cohesive system.

In short, NetSuite WMS Integration is the cornerstone of a connected warehouse:

One platform.

One data source.

Zero sync errors.

It’s how operational precision becomes business scalability.

Next Step: Explore how Versich’s certified NetSuite consultants can help your organization implement, optimize, and scale WMS for true end-to-end visibility. Schedule your strategy session today.